- MIG

What Is Pulse MIG Welding? When & Why Should You Use It

By Sarah Mazlin

27/10/2025

14 minutes

In This Article

- What Is Pulse MIG Welding?

- What Is Double Pulse MIG Welding?

- Why Would You Pulse MIG Weld?

- What Is Pulse MIG Welding Used for?

- What Metals Can You Weld With Pulse MIG?

- Pulse MIG Weld Cycle, Settings & Controls

- Advantages of Pulse MIG Welding

- Disadvantages of Pulse MIG Welding

- Pulse Transfer vs Other Metal Transfer Modes

- Optimising Your Pulse MIG Welds

- Which Gas Do You Need to Pulse MIG With?

- Is It Worth It?

- How Much Does a Pulse MIG Welder Cost?

- Pulse MIG Machines by UNIMIG

Pulse welding is a type of welding that lets you alternate the amperage between a ‘peak’ and ‘base’ amperage. It gives you more control over the arc, lower heat input and full penetration.

Pulse MIG welding works in the same way, but it comes with extra options and adjustments for even more control over your welds. We’ve covered what pulse MIG is, how it works and when you should use it.

What Is Pulse MIG Welding?

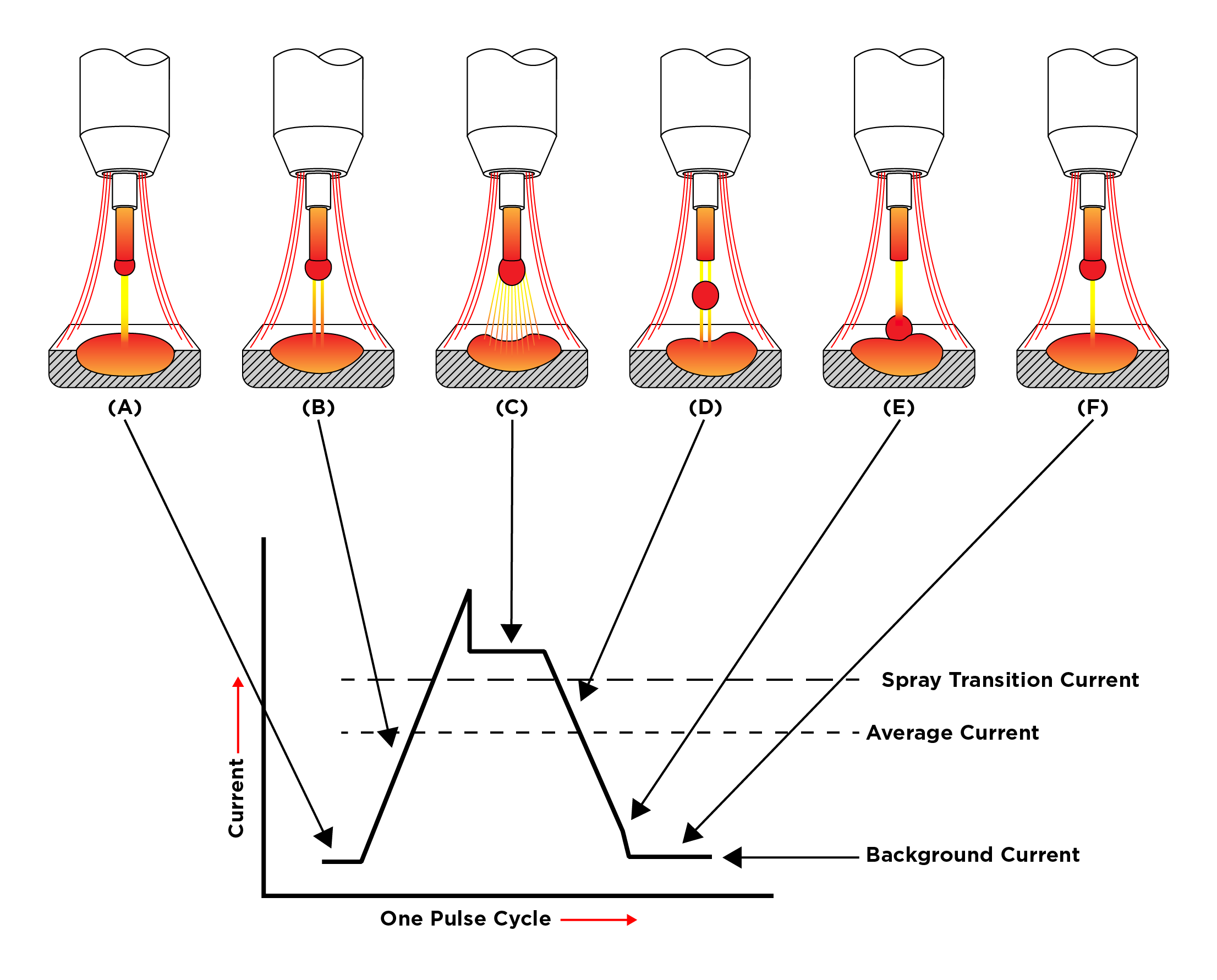

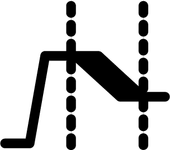

Pulse MIG welding is an advanced spray transfer method of MIG welding where the current alternates (pulses) between a high and low value for one pulse cycle.

Unlike standard short circuit MIG, spray transfer transfers the filler wire into the weld pool without contacting it. Instead, when the current reaches its peak, a droplet of wire is ‘pinched’ off the end and sprayed into the weld joint. The background current (or low point of the cycle) maintains the arc at a level that prevents a short circuit from happening.

Switching between the high and low current allows for ‘cool’ periods in the weld, which can significantly reduce your heat input. It also works to create the same ‘stacked dimes’ effect that is normally only achievable with TIG welding.

Single pulse MIG welding gives you all the benefits of a standard spray transfer, like faster welding speeds, no spatter, and deep penetration without the excess heat.

What Is Double Pulse MIG Welding?

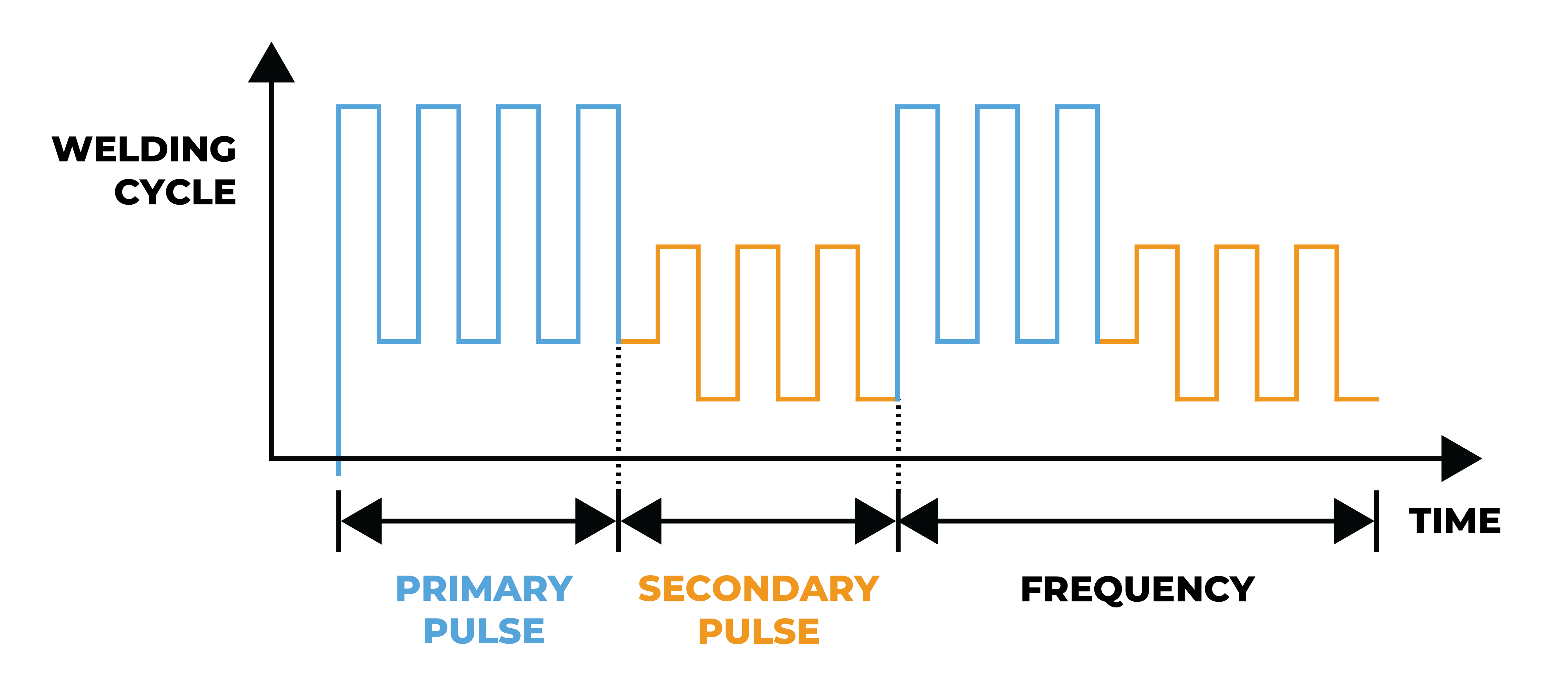

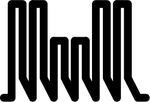

Double pulse, also known as pulse-on-pulse, MIG welding is similar to single pulse welding, but there are two pulses during the weld cycle. There are variations in the peak current pulses, which create a secondary waveform within the primary pulse.

The first pulse (pulse 1) is your standard pulse with a peak and base (background) current.

The second pulse (pulse 2) is similar to the primary pulse, but the peak current is further modulated, or lower, than the primary peak amperage and this creates additional, smaller pulses within the main pulse.

To make the most of a double pulse, leaving the base of the second pulse cycle low is recommended. The extra moment the weld pool has to cool gives you even more control over the heat input and creates the ‘stacked dime’ TIG look in the final weld.

Why Would You Pulse MIG Weld?

Pulse MIG welding comes with a number of advantages, which we’ve covered in depth below, but the main reasons why you would want to pulse MIG are:

- The lower overall heat input, which minimises distortion in the metal and reduces the chances of burning through, especially on thin sheet.

- Higher weld deposition, so you can weld at a faster travel speed and increase your efficiency.

- Better weld pool control, the cool periods of the pulse cycle means the puddle is fluid but fast freezing, which works well in all welding positions, including vertical up and overhead.

- Minimal spatter, as pulse MIG welding produces almost no spatter because of the spray pulse metal transfer mode, reducing your post-weld cleanup.

- Aesthetic welds, the ability to create the ‘stacked dimes’ effect with your MIG welder, means every weld will look good.

- Reduced welding fumes.

What Is Pulse MIG Welding Used for?

Pulse MIG welding can be used for almost any application you want, but it shines when used on aluminium, stainless steel and other uncommon materials like bronze. It’s also perfect for welding on thin sheet where minimal heat input is critical or on welds that are going to be visible.

Pulse MIG welding is commonly used in industries like automotive, marine, aeronautical and manufacturing, where minimal heat input, precision, speed, quality control and the appearance of the weld are essential.

What Metals Can You Weld With Pulse MIG?

Pulse MIG welding can be done on all metals but is preferred for applications where the heat input and weld pool control are critical or on welds that need to be visually appealing. You can pulse MIG weld:

- Aluminium

- Stainless steel

- Bronze

- Nickel alloys

- Specialty steels like high-strength and high-carbon steels

- Mild steel

The most common of these metals are aluminium, stainless steel, bronze and mild steel.

Pulse MIG Welding Aluminium

Aluminium is highly thermally conductive, which means it’s very good at drawing heat away from the weld pool. That, combined with its low melting temperature (660°C), makes pulse MIG an ideal welding process to get full penetration without distorting the metal or burning through.

Pulse MIG Welding Stainless Steel

Stainless steel, in contrast, is not very thermally conductive, which means it retains heat in the weld. Stainless steel is very easy to warp or distort because of this, and too much heat in the weld can cook out the chromium that gives it its ‘stainless’ properties.

The heat input control you have when pulse MIG welding on stainless steel allows the weld to cool, minimising distortion and preventing any overheating that can be typical of standard MIG.

Pulse MIG Welding Bronze

Bronze, or in particular bronze wires, are generally applied in a method called MIG brazing. That means the bronze is applied at a lower temperature than the base metal’s melting point. The bronze is ‘stuck’ on rather than welded together.

Bronze brazing is often used on thin sheet like car body panels where low temperatures and minimal distortion are essential. It is also commonly used on zinc-coated and galvanised steels because the low temperatures mean the coating isn’t evaporated and can’t produce toxic fumes.

Pulse MIG Welding Mild Steel

Mild steel doesn’t present any issues when it comes to its thermal conductivity and ability to weld. While you can pulse MIG it, there are not necessarily any benefits besides an appealing weld unless you’re welding on sheet metal, in which case you get the benefits of a lower heat input and less distortion.

Pulse MIG Weld Cycle, Settings & Controls

Pulse MIG welding is an advanced type of welding, and it comes with a lot of parameters and adjustable settings. These settings mean you can fine-tune the weld exactly how you want it, but it does take some extra time to learn them all.

Both single and double pulse MIG welding can either be synergic or non-synergic. A synergic machine means the welder will pick all the best settings based on your parameters. A non-synergic machine means you’ll need to input every value yourself, which can take a bit of trial and error and experience to get right, especially for double pulse.

Using our RAZOR 200 PULSE as an example, which is a synergic machine, let’s go over the pulse MIG cycle and the general settings you should have available. The ‘current’ referenced is the synergic combination of the selected voltage and wire feed speed (amps).

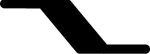

Hot Start Current

The hot start current determines the current your arc will start at. It is set as a percentage of the peak current (from 20% up to 150%), so your weld can start hotter or colder. Setting your hot start below 100% on our machine will result in a cold start.

Starting your weld with an extra current boost can eliminate the issue of starting aluminium on cold metal and break through the oxide layer.

Hot Start Timer

The hot start timer determines how long your hot start current will run before it returns to the peak current.

Hot Start Slope

The hot start slope determines how long it will take for your hot start current to reach the peak current, whether it gradually changes or switches instantaneously.

Main Current

The main current determines the average welding current you’ll select when inputting your voltage and wire feed speed. When single pulse welding, the machine will synergically select a peak and base amperage based on your parameters, and the displayed current is the average of these.

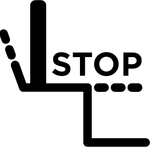

Stop Slope

The stop slope determines how long it will take for your peak current to reach your stop current, whether it gradually changes or switches instantaneously.

Stop Current

The stop current determines the current your arc will finish at. It is set as a percentage of the peak current (from 20% up to 80%) so that you can ease off the end of the weld and fill in your puddle, eliminating craters or cracking.

Stop Timer

The stop timer determines how long your stop current will run before it shuts off completely.

Arc Length

The arc length adjusts the distance between the end of your wire and the weld pool. Too long an arc length will cause excessive spatter and produce a wider, flatter weld bead. Too short an arc length lowers the voltage and produces a higher weld bead profile.

All of the above settings are available in single and double pulse modes, but when double pulse welding, you have a few extra settings that can be adjusted.

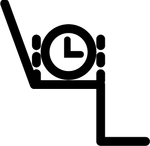

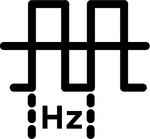

Double Pulse Frequency

The double pulse frequency determines how many times an entire pulse cycle will be completed in 1 second. Setting your frequency to 0.5Hz means it will take 2 seconds to complete a double pulse cycle, whereas, at 5Hz, your double pulse will complete 5 full cycles in 1 second.

Double Pulse Mode

The double pulse mode lets you choose between standard and advanced modes.

In standard mode, the double pulse settings are completely synergic, and the machine will select optimal settings based on your inputted parameters.

In advanced mode, you can manually adjust the double pulse low current and balance, so you have more control over your weld profile.

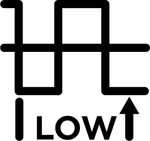

Double Pulse Low Current

The double pulse low current determines how low the current is of your double pulse. It is set as a percentage of the main current (from 10% up to 90%) so that you can choose how hot or cold your pulse weld is.

Double Pulse Balance

The double pulse balance determines how long will be spent in the main pulse and the second pulse. It is set as a percentage (from 10% up to 90%), so you can choose how long each part of the pulse cycle is. The more time spent in the main pulse, the hotter the weld, and vice versa.

The RAZOR 200 PULSE also lets you adjust your pre- and post-gas timer, as well as your inductance and burnback, for extra fine-tuning of your welds.

|

|

|

Advantages of Pulse MIG Welding

Pulse MIG welding has a lot of advantages over conventional MIG welding, including:

- Spatter-free welds

Pulse welding is a type of spray transfer, so the wire isn’t touching the puddle and being ‘thrown’ out. Instead, the filler is deposited directly into the weld rather than on the surrounding surface.

No spatter also means you don’t have to spend as much time cleaning up or doing post-weld work.

- Less heat input

With the addition of the low current in a pulse weld, your overall heat input into the joint is lowered. That means welding on thin materials and sensitive metals like stainless steel and aluminium is much easier. It also helps reduce the chances of distortion, warping and burn through.

- Directional control over the weld pool

Most pulse MIG machines can adapt their arc as they go. If the arc length changes throughout the weld, the machine can often account for this. That means any issues you might experience with an inconsistent arc length in a standard MIG weld are reduced, and the weld consistency and appearance are improved.

This is great for those without as much experience welding; they can still produce a quality weld with a good bead appearance.

- Weld pool control

The ability to adjust and fine-tune the arc as much as you can with a pulse MIG means you have more control over the weld pool. It can be tailored to suit any application you want to use it on. A tighter, narrower arc is perfect for thin joints or deep penetration.

It can also be widened and is a great choice when bridging root gaps, as the puddle manipulation and the faster freezing weld pool means root passes can be done faster and easier.

- Improved control over arc starts and stops

The start and stop current settings that are available on pulse MIG machines help eliminate most issues a welder usually faces when starting or stopping a weld. The increased heat on ignition helps to penetrate the beginning of the weld, while the background current prevents burn through.

Similarly, the stop slope and stop current allow you to fill in the end of the weld without shocking the metal, minimising the chances of a crater or crack forming at the end of the weld.

- Improved productivity with higher deposition rates

Pulse MIG welding has a higher deposition rate than standard MIG, which means you can increase your wire feed and travel speeds, increasing your productivity.

- Weld thick or thin materials

Pulse MIG welding is ideal for welding on thin materials and sheet metal, but it’s just as capable when welding thick plate as well.

- Aesthetic welds

The fast-freezing action of the weld pool leaves you with an aesthetic weld bead every time, and double pulse welding can produce the same ‘stacked dimes’ effect that TIG welding is known for.

- Reduced welding fumes

Less welding fumes are produced while pulse MIG welding, so you’re not breathing in as many, creating a healthier working environment.

- Out-of-position welding

While pulse MIG is a type of spray transfer, the addition of the low current in the cycle means the weld isn’t as hot as standard MIG spray transfer. Because the puddle is less fluid, controlling it in out-of-position welds, like overhead and vertical up welding, is easier.

Disadvantages of Pulse MIG Welding

While pulse MIG welding is a good choice for a wide range of applications, it still has its disadvantages:

- It’s expensive

The main downside to pulse MIG welding is that it can be an expensive investment. A pulse MIG machine will cost more than a standard MIG machine with the same output power due to the extra internal components that make it capable of producing a pulse.

- Some machines are non-synergic

While every UNIMIG pulse welder is synergic, not all machines are. A non-synergic pulse MIG welder will require you to input every setting manually, which will take longer and can be difficult if you’re unfamiliar with the process.

- Pulse MIG welding doesn’t remove the surface oxide

Pulse MIG welding doesn’t remove the surface oxide. While AC TIG welding can break through the surface oxide because it alternates between DCEP and DCEN, this is not true of pulse MIG.

Pulse MIG alternates between a high and low current, but it’s fixed in DCEP, so it can’t clear the oxide as it welds the same way an AC TIG weld can.

When using pulse MIG on aluminium, your base metal needs to be cleaned thoroughly before it’s welded, as the arc doesn’t remove the oxide layer.

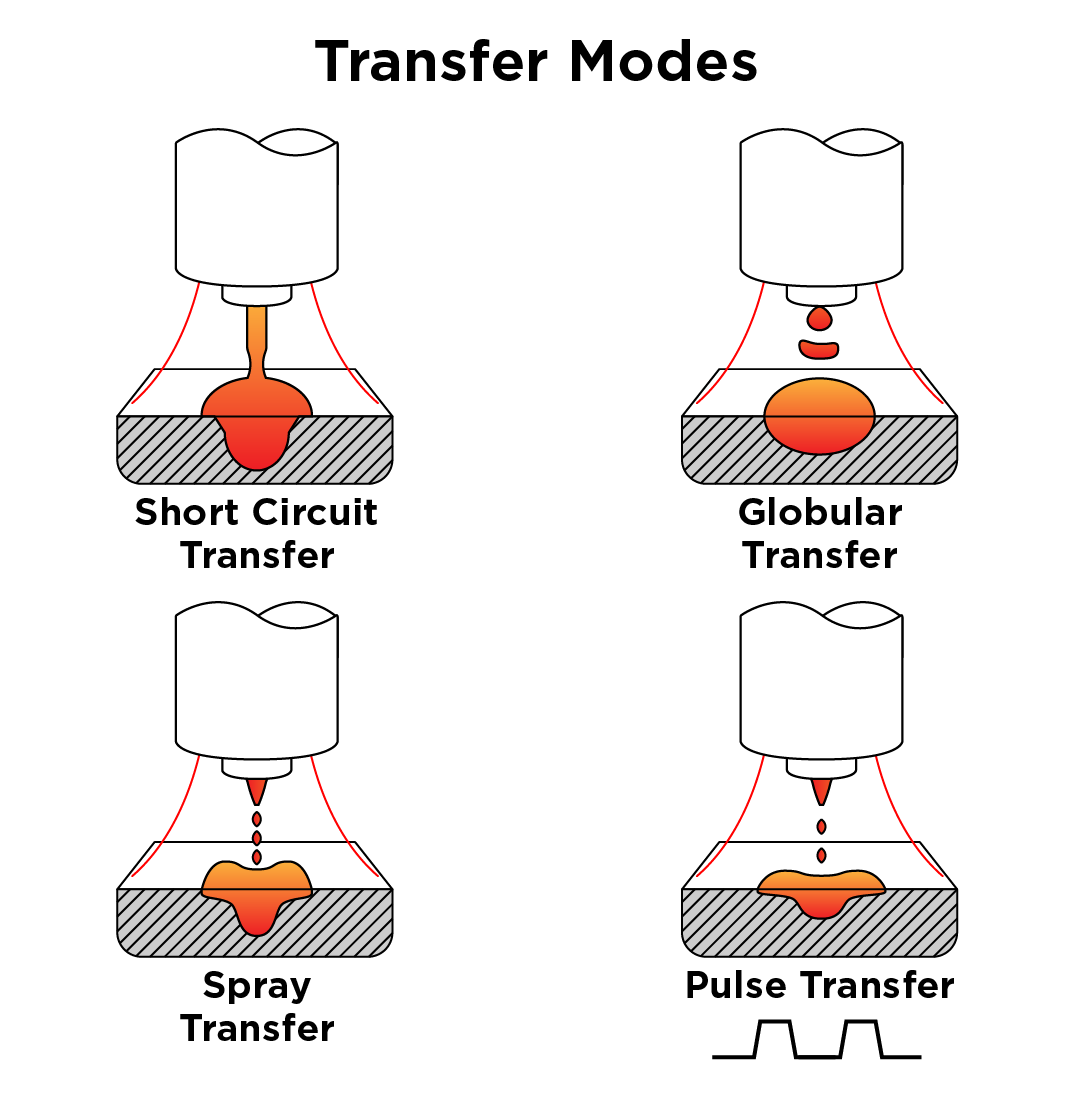

Pulse Transfer vs Other Metal Transfer Modes

The pulse transfer method works differently than the other metal transfer modes and comes with its own benefits.

Pulse vs Short Circuit

Short circuit wire transfer is the most basic and most common MIG transfer mode for welding 6mm and under. A short circuit transfer occurs when the wire is fed from the torch into the weld puddle, where it short circuits and melts into the joint.

Every time a short circuit happens, the molten wire explodes and propels spatter outwards. In comparison, pulse MIG spray transfer ‘sprays’ the wire into the joint. It never makes physical contact with the weld pool, so there is no spatter.

Pulse vs Globular

Globular wire transfer occurs when the wire forms a large ball or glob of molten metal at the tip that falls into the weld puddle. It often explodes when the wire makes contact with the pool and short circuits, creating excessive spatter.

Globular wire transfer needs a higher current than short circuit to run but is lower than spray. Globular is also the least common transfer method used because of the excessive spatter and potentially uneven weld. In comparison, pulse MIG is better in every way.

Pulse vs Spray

Spray wire transfer occurs when the wire feed speed and voltage output are high enough that the wire begins to spray tiny droplets into the weld pool. Spray transfer is also spatter-free and great for heavy fabrication and thick materials.

However, it’s so hot and fluid that it’s not suitable for thin materials or welding out-of-position (vertical up or down and overhead). That’s where pulse spray comes in. With all the benefits of the spray transfer that occur during the high current and a cooling low current period that prevents burn through and lets you weld out of position.

Optimising Your Pulse MIG Welds

A synergic pulse MIG welder is designed to work straight out of the box, but there are still a few extra things that you can do to help improve your final results.

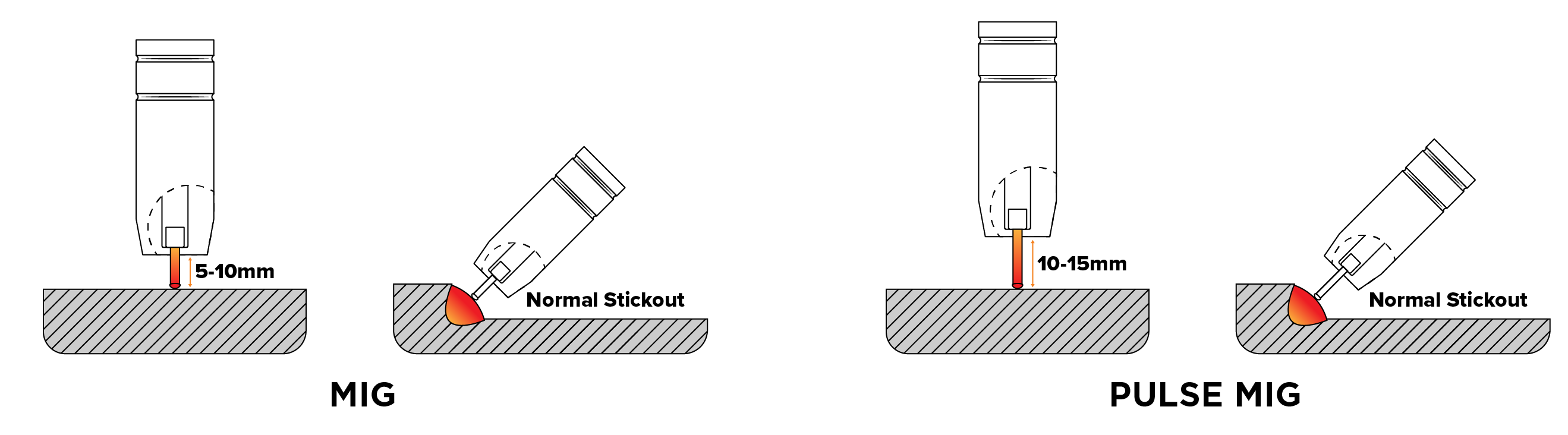

1. Stickout & Technique

When standard short circuit MIG welding, the recommended wire stickout is roughly 10mm (1cm) long, which keeps the arc stable.

When pulse MIG welding, you’ll need to extend your stickout to roughly 15mm because of the more fluid bead.

You’ll also need to push your weld at a 10°-15° travel angle for the best results.

2. Check Your Earth Clamp

Pulse MIG welding requires a really good earthing, so check your cables and make sure your earth clamp is connected directly to the workpiece.

Which Gas Do You Need to Pulse MIG With?

You’ll need a gas mixture with at least 80% argon to get into a spray transfer, so you can’t use a standard MIG gas mix.

For mild steel, an Ar/CO2 mix from 82%/18% to 92% /8% gas mixture is needed. 92%/8% is the most commonly used for pulse MIG welding steel.

For stainless steel, which can’t tolerate as much CO2 as mild steel, the standard stainless 98%Ar/2%CO2 (known as C2 gas) can be used. The lower CO2 content prevents sensitisation in the metal.

For aluminium, pure argon is needed. All aluminium MIG welding should be done with pure argon or an argon/helium blend, as CO2 can’t be used.

Is It Worth It?

If you’re trying to decide whether a pulse MIG is going to be a worthwhile investment for you, there are a few factors to consider. Your specific welding needs, the material you frequently work with, how much welding you need to do, and your budget.

If welding is your primary source of income, or you’re doing lots of work on pipes, car part repairs, doing a lot of aluminium or stainless steel welding, or need to increase your productivity, a pulse MIG is worth it.

The only situation that a pulse MIG welder might not be worth the expense is if you’re a hobby DIY welder who only gets to weld occasionally.

How Much Does a Pulse MIG Welder Cost?

A pulse MIG machine usually costs several thousand dollars, even for a smaller, single-phase machine. This price increases as you move into higher output (like 500A) three-phase pulse welders.

Pulse MIG Machines by UNIMIG

At UNIMIG, we have some of the most affordable, top-quality, single-phase pulse MIG machines available.

The ENVY MULTI 250 AC/DC comes packed with features, including:

- Single & double pulse MIG plus manual & Smart-Set MIG modes

- A 7” LCD touchscreen display

- Multi-process, so you can also high-frequency AC & DC TIG plus stick weld

- Additional accessories including water cooler, separate wire feeder & trolley allow for extra flexibility