- MIG

- TIG

- MMA

Welding Overlap: What Is It, What Causes It & How to Prevent It

By Sarah Mazlin

29/09/2025

4 minutes

One of the common weld defects that you can get is overlap. It can occur on MIG, TIG and stick welds, and once you’ve got it, it’ll need to be addressed.

We’ve covered what overlap is, what causes it, the best ways to go about avoiding it, and how to fix it if you do get it.

What Is Welding Overlap?

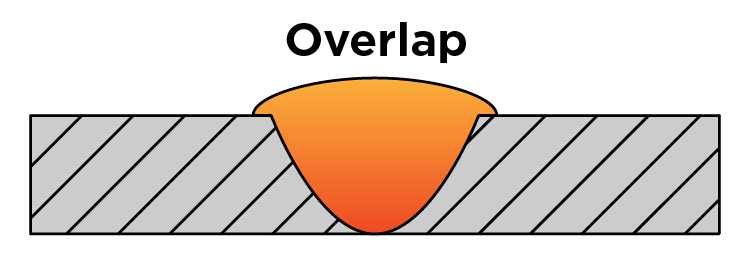

Overlap on a weld occurs when there is too much metal in the weld bead, which spills over the edges of the base metal and doesn’t fuse into it. Overlap is sometimes referred to as ‘cold lap’.

Overlap is classified as a weld defect because the edges of the weld aren’t fused with the base material, creating a weaker weld.

As well as making the weld joint weaker, it also affects the appearance and overall cost of the weld. Overlap on a weld doesn’t look pretty, plus it means more filler metal than necessary is being deposited. If that’s happening over and over, you’ll be going through filler faster than expected, increasing the overall cost of any work being done in the long run.

What Causes Overlap on a Weld?

There are four main causes of overlapping:

- Amperage/voltage

- Travel speed

- Electrode size & angle

- Metal preparation

Not Enough Volts or Amperage

If your voltage (when MIG welding) is too low or your wire feed speed is too high, you’ll have too much filler metal being deposited into the weld without enough heat. If the additional filler is more than what’s needed, it’ll spill over the edge and onto the base metal, giving you overlap.

When stick or TIG welding, too low an amperage will mean the metal won’t fuse into the toes properly and leave you with overlap.

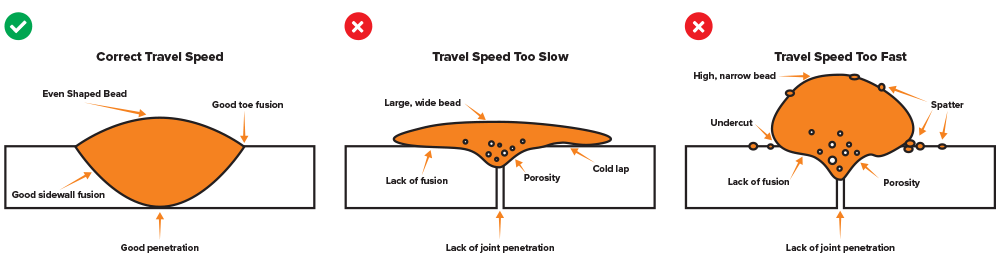

Too Slow a Travel Speed

Travelling too slowly along the joint will also often result in overlap. The rate at which the filler metal is being deposited is constant, so if you aren’t moving fast enough, it’ll build up in your weld pool (causing a convex bead) and then overflow.

Incorrect Filler Size & Angle

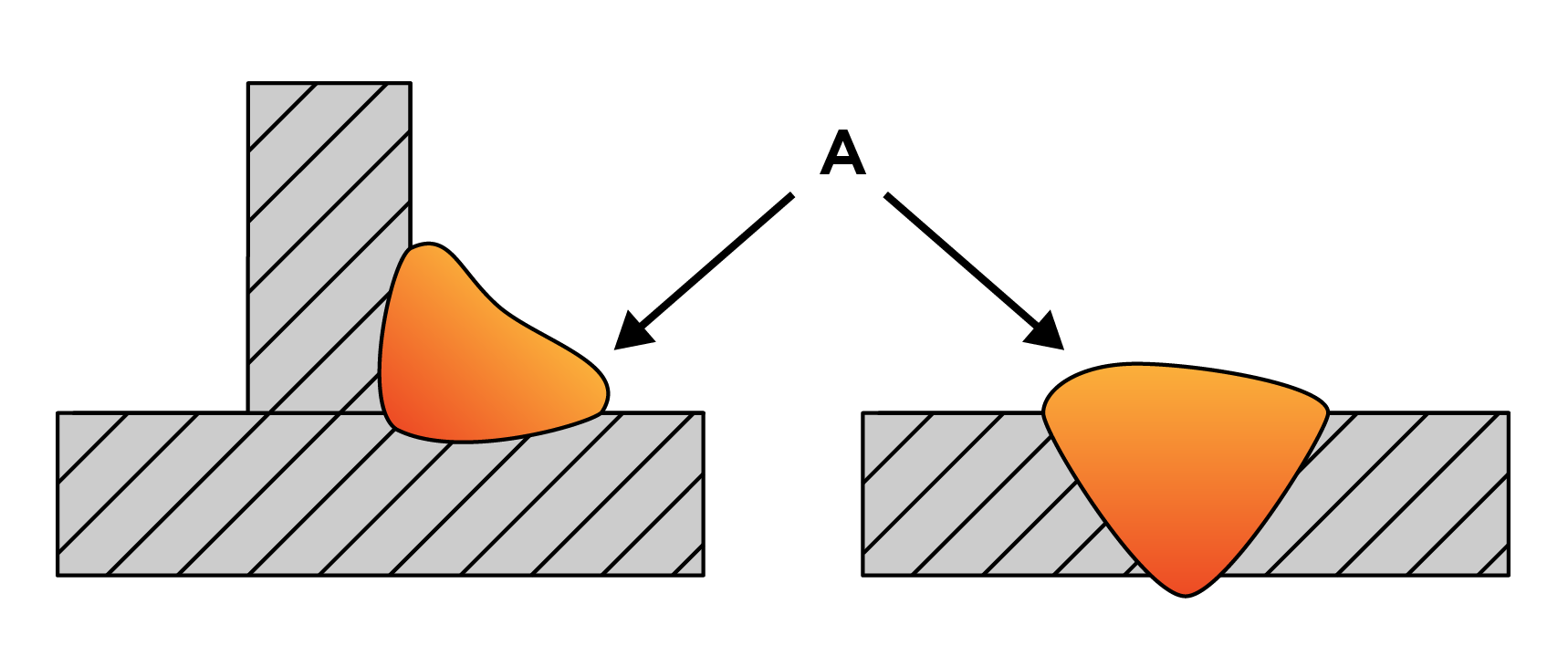

If you’re welding at the wrong angle, or if you’ve picked a filler wire, rod, or electrode that’s too large, you can get overlap.

How you hold your torch and the angle at which your filler metal is deposited into your weld will impact the penetration and placement of the weld bead. If your travel angle is too shallow or too deep, or your arc isn’t centred in the joint, you could get overlap.

If your choice of filler material is too big for the metal thickness you’re welding, the excess metal will build up in the joint, and once it’s too full, it’ll spill over, causing overlap.

Not Properly Prepping the Metal

How well you prepare and fit your metal will impact whether you get overlap. A joint with burrs or uneven surfaces will cause problems, as will poor joint fit up.

How to Prevent Overlap

To prevent these causes of overlap, you can do the following:

Adjust Your Machine Settings

If your wire feed speed is too high or your voltage or amperage is too low, you’ll need to adjust it to prevent overlap.

If you’re not sure what your machine should be set to, check out a settings guide. Most MIG machines will include one inside the door. Or, for TIG and stick settings, you can check out the Ultimate Welding Guide for a good starting point.

Once you’ve set your machine to a recommended amperage, it’s always a good idea to test those settings on some spare metal and do a few test runs. That way, you can fine-tune them to your weld before you go ahead on the real thing.

If you’re getting overlap while testing the settings, adjust them until you don’t.

Increase Your Travel Speed

If you’re travelling too slowly and getting excessive weld buildup, speed up. You don’t want to go so fast that you end up with other issues in your weld, but enough that your filler metal melts into the base metal without any overflow.

Get the Right Electrode & Alter Your Angle

Getting your filler size and placement right is crucial to making a good weld, not just for preventing overlap.

The angle you add your filler metal to the weld should be a 10°-15° (from vertical) push or pull angle, depending on the type of welding you’re doing. You should also make sure that your arc is pointed directly into the centre of the joint so that you get even placement across the weld.

You also want to make sure you’re using a filler wire, rod, or electrode that’s the correct size for the material thickness. If it’s too large, it’ll need extra heat to melt in and will add too much metal to the joint. If it’s too small, there won’t be enough to properly fill the joint.

Properly Prep Your Metal

Clean your base metal thoroughly and make sure that your joint edges are smooth and lined up evenly, so the plates don’t overlap on one side with a large gap on the other.

If your plates aren’t lined up nicely, you can run into quite a few problems, including overlap.

How to Fix Welding Overlap

Like other weld defects, to fix overlap on a weld, you’ll need to feather the part of the weld that overlaps back to sound weld metal and a mitred profile. This is usually done with a fine enough grinding disk that allows you to grind only the overlapped part of the weld. Be careful when doing this to not remove too much of the weld metal and leave the joint underfilled.