- MIG

- TIG

- MMA

The Different Types of Weld Positions: A Comprehensive Guide

By Sarah Mazlin

22/12/2025

14 minutes

Whether you’re a seasoned professional or just starting, understanding the different types of weld positions is important for anyone involved in the welding process.

These positions are classified based on the orientation of the welding being done. Knowing what each position is and how to go about welding them will help you get strong and durable welds and ensure your safety.

There are four main welding positions: flat, horizontal, vertical, and overhead. Each position has its own unique characteristics and challenges. For example, the flat position is generally the easiest to weld in because gravity helps to hold the molten pool in place. Meanwhile, welding overhead presents a challenge as you’ll need to tackle gravity directly, requiring a higher skill level to prevent the weld bead from sagging or dripping.

As well as welding the joint in a certain position, you’ll want to know how to adapt your technique for each weld position and joint type so you can create solid, reliable welds. The common basic joint types you’ll encounter are fillet and groove. These techniques can significantly impact the quality and strength of the finished weld.

The Basics of Welding Positions

The four welding positions are defined by the workpiece’s orientation and the weld’s direction.

- Flat position

The flat welding position is where your workpiece lies flat, and you perform the weld on the top side. - Horizontal position

The horizontal welding position is where your workpiece is horizontal, and you’re welding horizontally. - Vertical position

The vertical welding position is where your workpiece is vertical, and the weld runs either upwards or downwards. - Overhead position

The overhead welding position is where you weld your workpiece from beneath.

The two basic types of welds you’ll be working with when welding in these positions are:

- Fillet welds: when two pieces are welded together at an angle or perpendicular

- Groove (butt) welds: when a groove is made between two pieces or at the edge

You’ll need to adapt your technique to accommodate each position and the behaviour of the weld pool. Maintaining a steady hand and controlling the weld are essential for creating strong, defect-free welds.

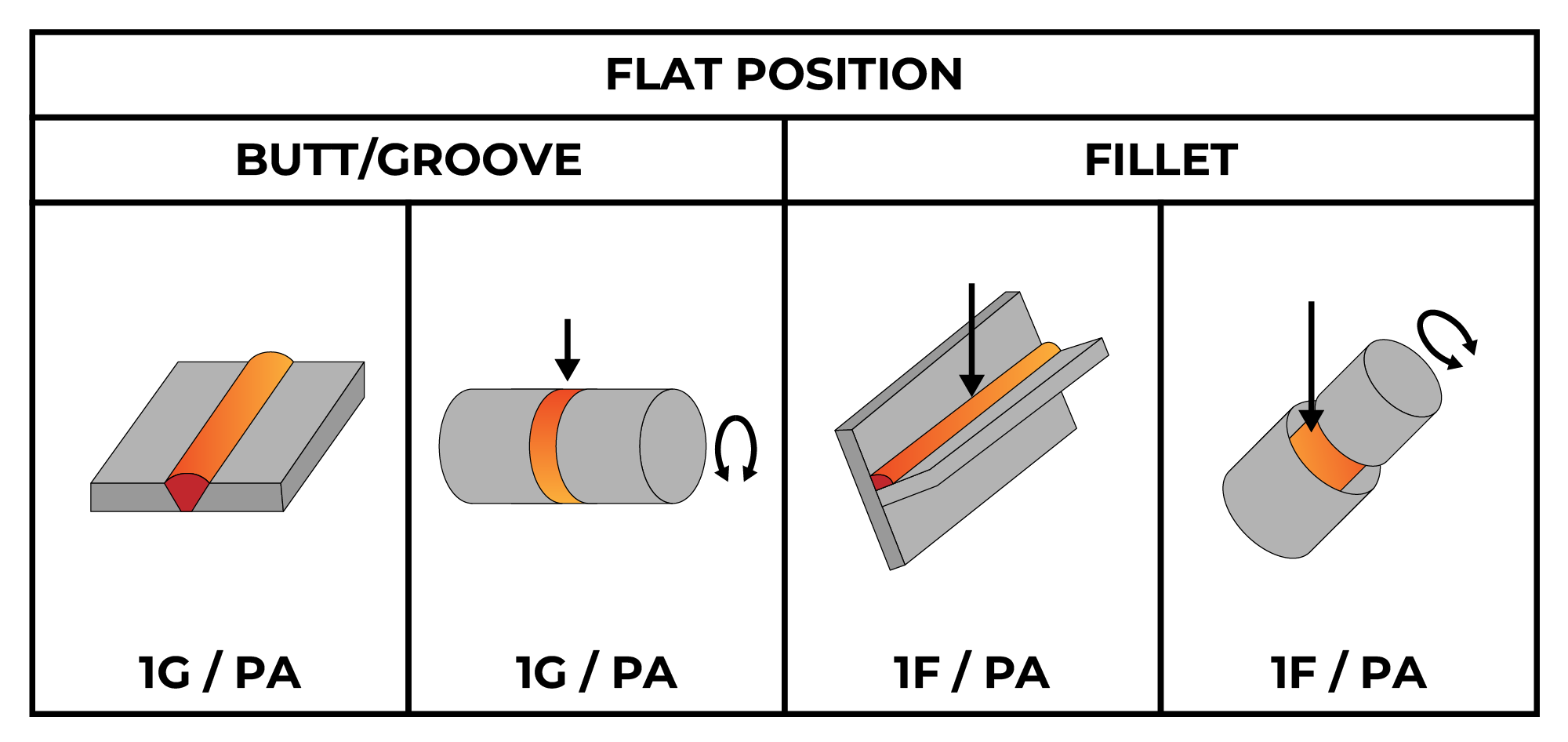

Flat Position Welding

When welding in the flat position, you lay the workpiece flat to weld on it. This position allows gravity to help distribute the molten metal evenly, making it one of the easiest positions to work in and ideal for beginners.

The flat position is referred to in several ways:

- PA position - EN standards

- 1G or 1F - American Welding Society (AWS)

The difference between 1G and 1F is that the ‘G’ indicates a groove weld, while the ‘F’ indicates a fillet weld.

How to Weld in the Flat Position

When doing a flat weld, the ‘technique’ involves placing the workpiece so that it is flat (either on a bench or fixed to the job), and you can weld along the joint horizontally.

The fluid weld pool is the easiest to control in this position as you add filler metal. It’s much less likely to flow out of the joint due to gravity, so you get an even distribution of the filler material along the weld.

Tips & Tricks for Flat Welds

- Make sure the welding surface is level when possible

- Practice steady hand movements and do a few dry runs before starting

- Maintain a consistent travel speed and distance from the workpiece

Challenges With the Flat Position

Despite its simplicity, the flat welding position does present some challenges:

- Travelling too slow and overheating the metal will cause distortion or burn through

- Too little or too much filler material may lead to a poor weld profile

To overcome these issues:

- Travel at a steady pace and adjust your welding machine settings to suit

- Use a stringer bead technique to get an even distribution of the filler metal

Keep in mind that using the proper technique will help you get flawless flat welds. This type of welding position is by far the easiest way to lay down a weld bead.

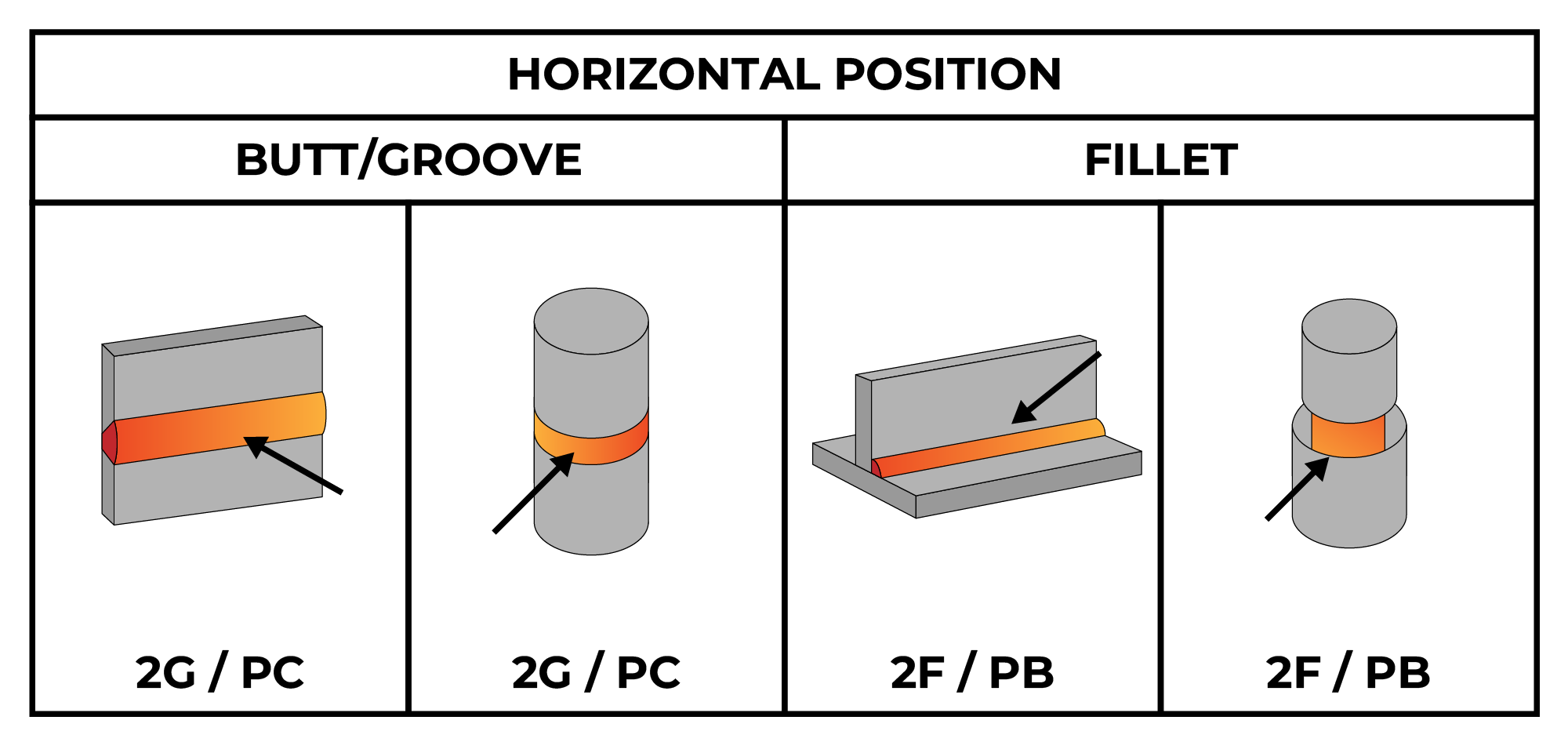

Horizontal Position Welding

When welding in the horizontal position, the workpiece is on a vertical axis, with the weld travelling horizontally. This position is trickier than flat welding because of the tendency of molten metal to sag or drip, which you need to prevent while welding.

The horizontal position is referred to in several ways:

- PB or PC position - EN standards

- 2G or 2F - American Welding Society (AWS)

The PB position refers to horizontal fillet welds, while the PC position refers to horizontal groove welds. The difference between 2G and 2F is that the ‘G’ indicates a groove weld, while the ‘F’ indicates a fillet weld.

How to Weld in the Horizontal Position

When doing a horizontal weld, you’ll need to manipulate the torch to maintain a consistent weld pool, as the force of gravity is more pronounced. To combat this effect, your torch angle and work angle to the joint need to be adjusted from a flat weld.

Tips & Tricks for Horizontal Welds

- Use the right torch angle to get an even distribution of heat in the joint

- Use the correct type and amount of filler material to prevent sagging

- Maintain a steady travel speed for a consistent bead appearance

Challenges With the Horizontal Position

While not the hardest type of weld, horizontal welding can cause some issues:

- It can be prone to defects like undercutting, porosity, or excessive convexity, which compromise strength

- Travelling too slow will deposit too much metal, causing it to drip out

To overcome these problems:

- Travel at a steady pace with some manipulation to keep the weld in the joint

- Adjust your welding machine settings to suit the position

By understanding the unique requirements of the horizontal position, you can improve the quality of your welds and ensure that they’re structurally sound and aesthetically pleasing.

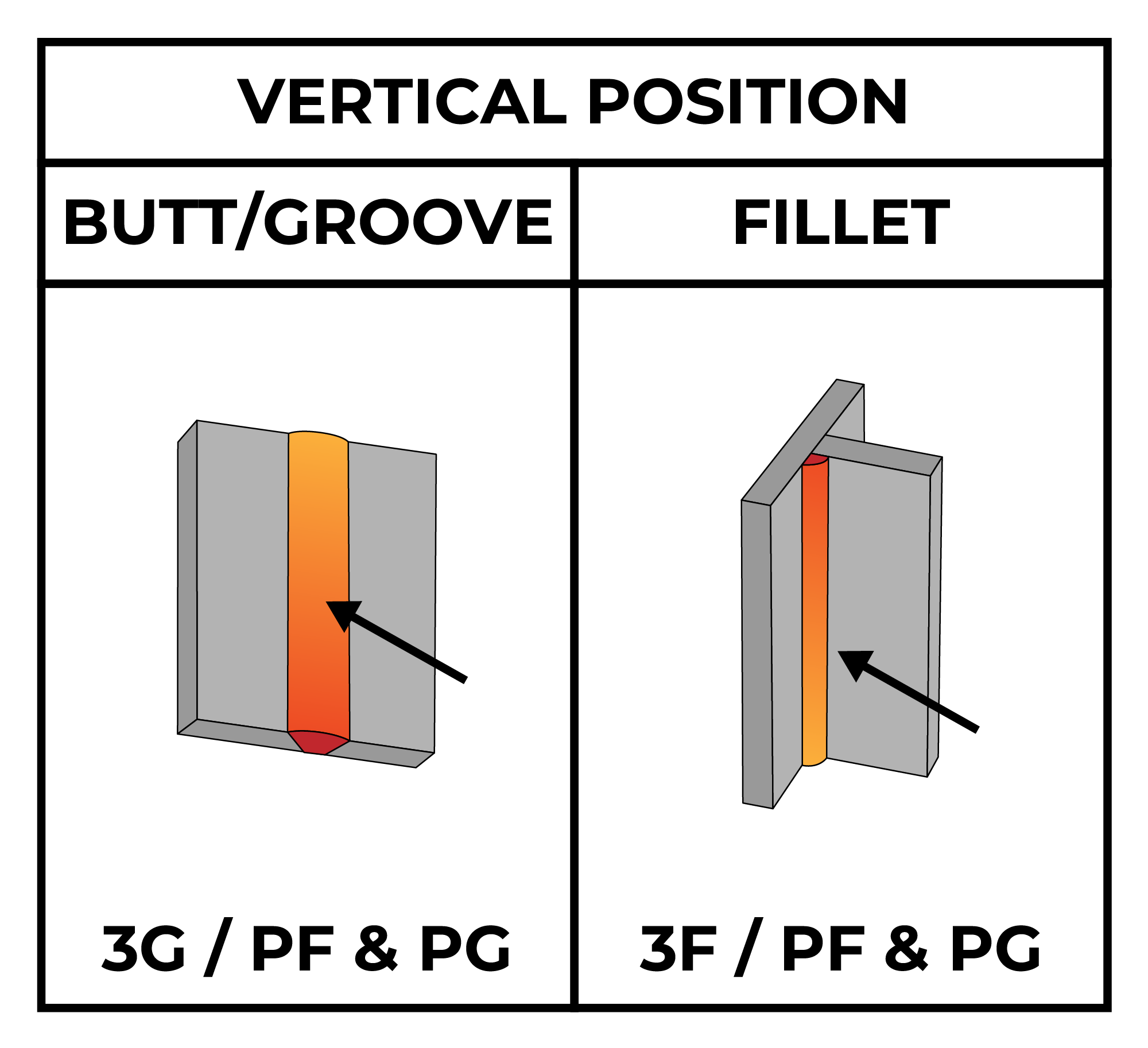

Vertical Position Welding

When welding in the vertical position, the workpiece will be on a vertical axis, with the weld travelling vertically. This position is harder because of gravity’s impact on the molten pool, which will be constantly trying to fall out the bottom.

The vertical position is referred to in several ways:

- PF or PG position - EN standards

- 3G or 3F - American Welding Society (AWS)

The PF position refers to welding vertically up, while the PG position refers to welding vertically down. The difference between 3G and 3F is that the ‘G’ indicates a groove weld, while the ‘F’ indicates a fillet weld. The AWS does not differentiate between travelling up or downwards on vertical welds.

How to Weld in the Vertical Position

You can achieve a vertical weld in two ways: vertical up and vertical down.

- Vertical up: this technique (3G, 3F and PF) is done by starting at the bottom of the workpiece and travelling uphill (upwards) along the joint

- Vertical down: this technique (3G, 3F and PG) is done by starting at the top of the workpiece and travelling downhill (downwards) along the joint

Both vertical welding techniques require a consistent travel speed and angle to keep the weld pool where it’s meant to be and get a strong joint.

Vertical welding is the main weld position that requires a lot of torch manipulation to control the weld pool. There are a lot of different techniques that can be used, but the most common is the triangle or ‘Christmas tree’, which helps to lead the puddle while you weld.

Challenges With the Vertical Position

Vertical welding is one of the harder types of welding to do, and there are a couple of problems you can face:

- If not done properly, you may not get proper penetration, which will compromise the strength

- Travelling too slow or having too much heat will allow the weld to drip out the bottom or run ahead of your weld pool

To overcome these problems:

- Use a good torch technique and travel at a steady pace to keep the weld in the joint

- Adjust your welding machine settings to suit the position; vertical welds usually need less heat input and, therefore, lower settings

Learning how to weld vertically will let you produce high-quality, strong welds on any joint. Controlling heat input and weld pool size is important to avoid distortion and maintain quality while counteracting gravity. Aim for a stable arc and smooth beads without defects as you improve your method.

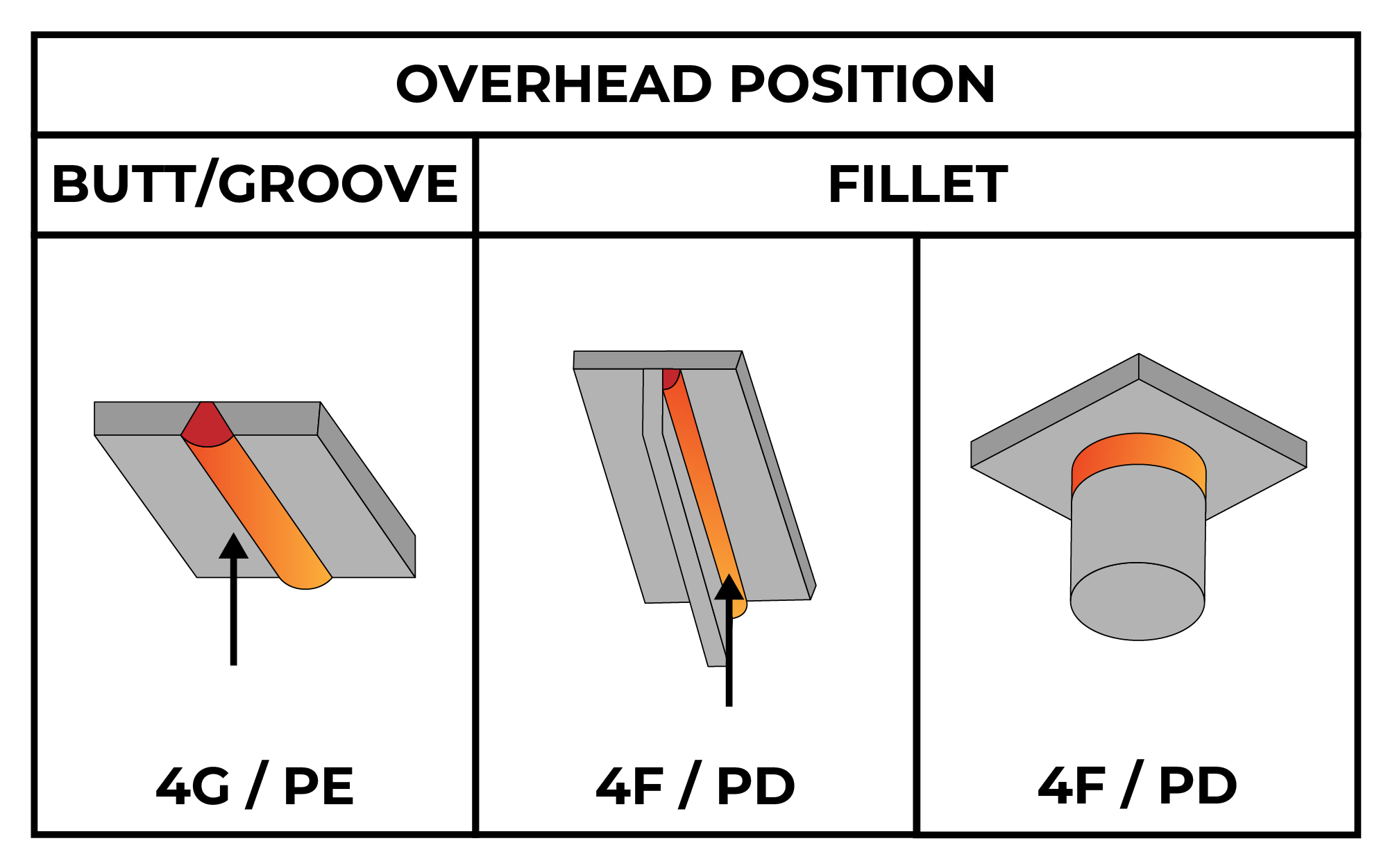

Overhead Position Welding

When welding in the overhead position, the workpiece will be above you, with you looking up at it, welding in a horizontal direction. This position is considered the hardest of all because of the impact of gravity on the weld pool, which can fall out of the weld completely and onto you.

The overhead position is referred to in several ways:

- PD or PE position - EN standards

- 4G or 4F - American Welding Society (AWS)

The PD position refers to fillet welds, while the PE position refers to groove welds. The difference between 4G and 4F is that the ‘G’ indicates a groove weld, while the ‘F’ indicates a fillet weld.

How to Weld in the Overhead Position

When doing an overhead weld, you’ll need to slightly manipulate the torch to maintain a consistent weld pool as gravity tries to pull your weld out of the joint. Overhead welding requires some skill, as you’ll want to travel quickly to get the weld laid down without compromising on penetration or introducing defects.

Tips & Tricks for Overhead Welds

- Lower your overall settings to keep the weld from getting too fluid and uncontrollable

- Use the correct type and amount of filler material to prevent it from dripping

- Maintain a good torch angle and a steady but fast travel speed for a consistent bead appearance

Challenges with the Overhead Position

Overhead welding is the hardest type of weld to do for a few reasons:

- The weld pool can fall out of the joint due to gravity

- It can be difficult to see and/or reach the workpiece, depending on where the overhead joint is

To overcome these problems, you’ll need excellent coordination and the ability to continuously adjust the torch angle.

You should also use a shorter arc length and reduce the machine settings to help maintain control over the weld pool, which is crucial for preventing the molten metal from dripping.

Equipment & Safety Measures for Overhead Positions

When welding in the overhead position, wearing the correct safety and PPE gear, such as a welding helmet, gloves, fire retardant jacket, long pants, and enclosed shoes, is essential. Not only do they protect your eyes from the bright light of the arc, but they also shield you from hot metal spatter. Here’s what you need to guarantee your safety while welding:

- Welding helmet: a quality helmet with appropriate filters to prevent eye strain and shield your face

- Protective clothing: fire-resistant garments covering all skin to avoid burns from falling spatter shield from UV rays

- Positioning: make sure you’re comfortably positioned and stable to maintain control over the weld

- Ventilation: adequate ventilation is crucial to avoid inhaling fumes, whether this is through respirators or fume extraction

It requires a high level of skill to maintain the quality while also controlling the weld, making it the most challenging weld position. By following these guidelines and using the right equipment, you can manage the challenges of overhead welding and maintain a safe working environment.

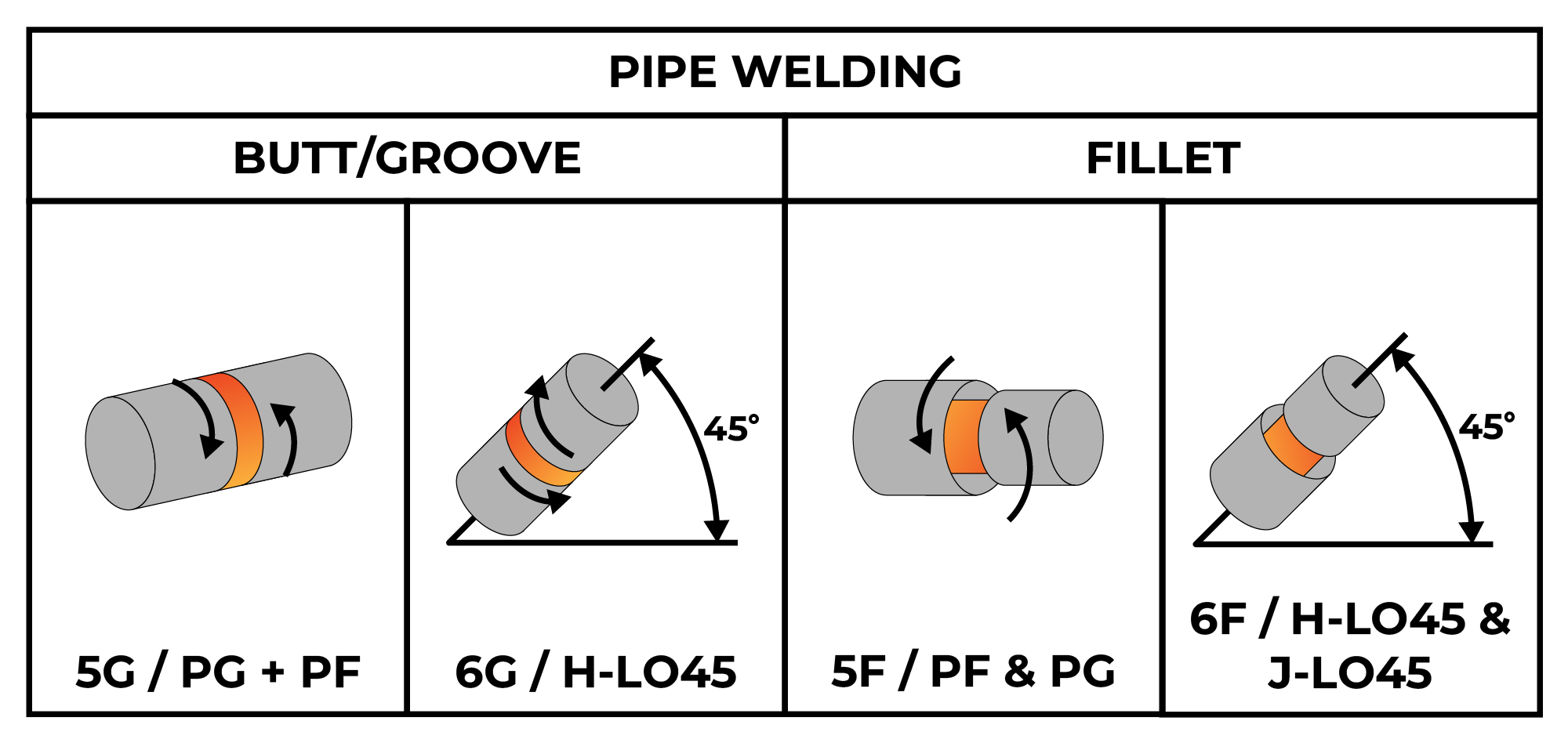

Advanced Pipe Welding Positions

On top of the four basic welding positions, there are a few advanced positions that are specific to welding on pipes. Pipe welding is generally more difficult than flat plates because you are required to stop and restart more often as you are forced out of position.

Not only do you need to be able to consistently restart a weld, but there’s also the issue of penetration and sugaring on the inside of the joint.

There are two different positions when it comes to pipe welding:

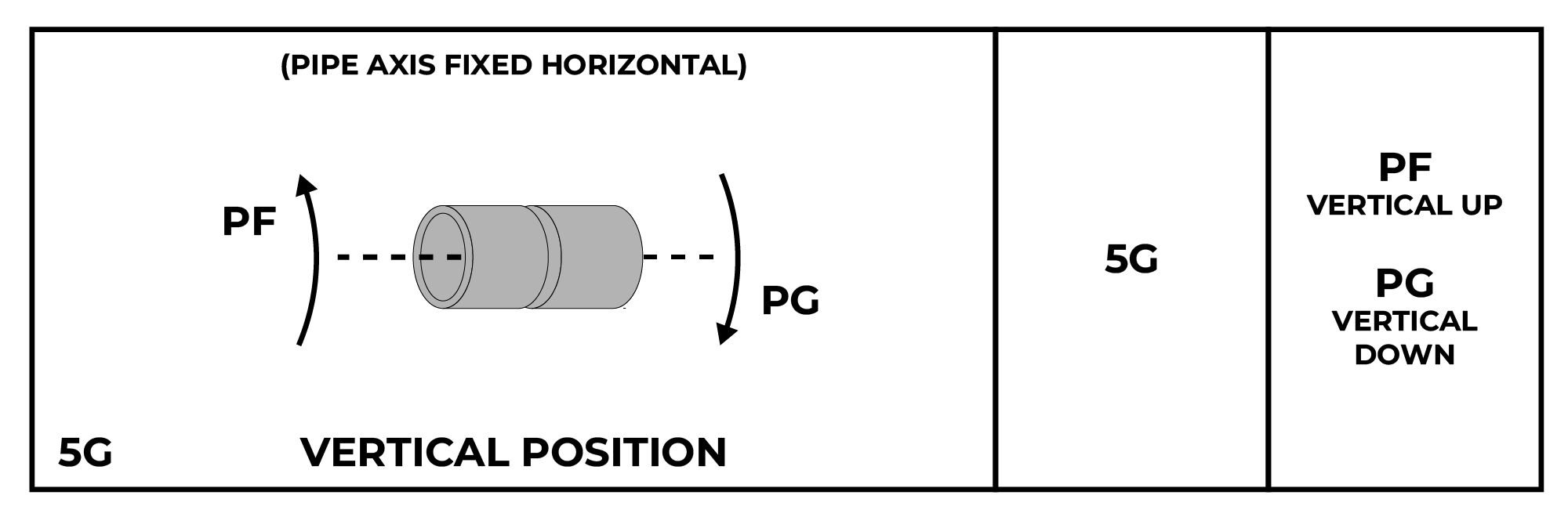

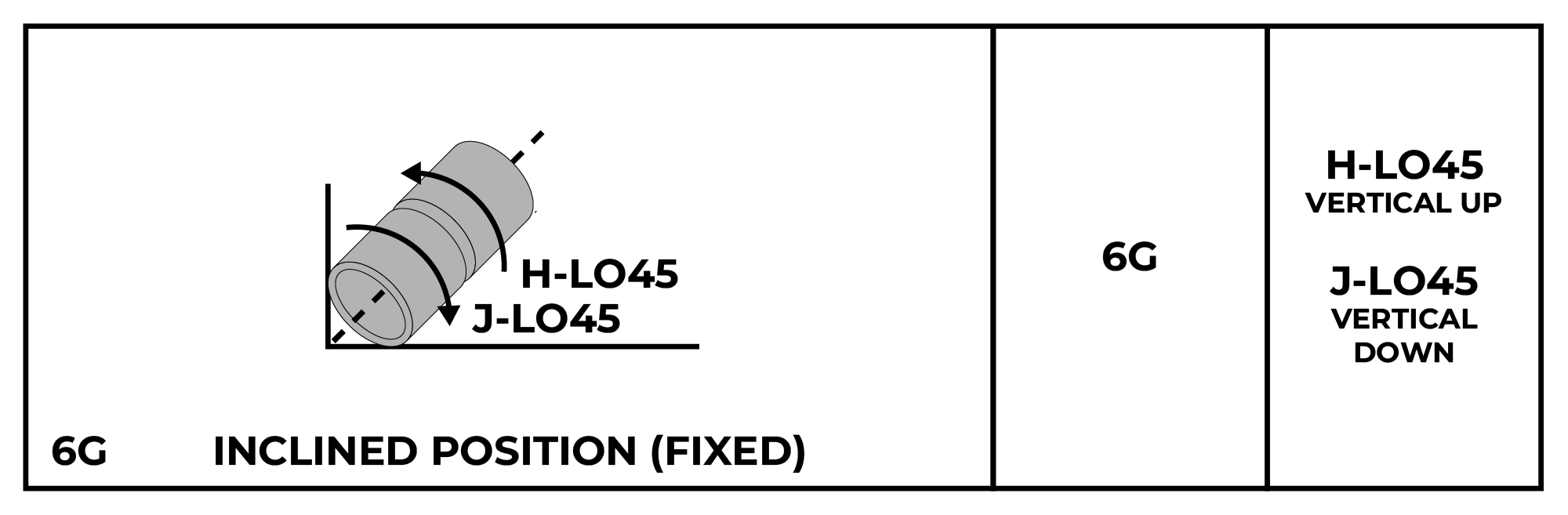

• 5G and 5F (AWS) or PF and PG (EN)

• 6G and 6F (AWS) or H-L045 and J-L045 (EN)

The PF and H-L045 positions refer to welding vertically up, while the PG and J-L045 positions refer to welding vertically down. The difference between 5G/6G and 5F/6F is that the ‘G’ indicates a groove weld, while the ‘F’ indicates a fillet weld. The AWS does not differentiate between travelling up or downwards on vertical welds.

As you delve into advanced pipe welding, understanding the complexity of these positions is crucial as they demand skill, knowledge of proper techniques, and adherence to strict quality control measures.

Understanding the Pipe Welding Positions

Like the other four main types, the layout, angle and weld direction impact the classification of the different welding positions.

5G/5F/PF/PG Position

This position is used for welding pipes that are fixed in a horizontal position. When you perform a 5G weld, you’ll move around the pipe, which is challenging because gravity affects the molten weld pool. Plus, if it’s already attached to the job by another weld, it can be difficult to navigate around, and you may find yourself out of position while welding.

The 5G uphill position requires you to weld upwards from the bottom of the pipe, offering better penetration and strength. On the other hand, the 5G downhill position involves welding from the top down, which can be faster but may compromise penetration and strength.

6G/6F/H-L045/J-L045 Position

This position is used for welding pipes that are fixed in an inclined position, which includes both inclined angles and requires you to weld on both flat and vertical planes. It’s one of the most challenging positions, combining aspects of all other positions and testing your ability to adapt to changing orientations.

To be considered an expert at 6G often involves mastering both the 6G uphill (H-L045) and downhill (J-L045) positions, reflecting a welder’s versatility and skill.

| Position | Pipe Orientation | Weld Type |

| 5G | Horizontal (fixed) | Butt (groove) weld |

| 5F | Horizontal (fixed) | T-joint/fillet weld |

| 6G | Inclined (fixed) | Butt (groove) weld |

| 6F | Inclined (fixed) | T-joint/fillet weld |

Welding Certification

To ensure a high level of experience, you’ll need to get welding certification through tests that assess your ability to weld in each and every position, including 5G and 6G.

Certifying bodies such as the American Welding Society (AWS), Australian Standards, and the International Organisation for Standardisation (ISO) set the benchmarks for the quality and safety of welding practices.

To get a welding certification, you’ll need to take a test at an RTO (usually while completing a welding course), and if your weld on that position passes, you receive the qualification for it.

Your welder certification tests a welder’s proficiency with different joint configurations, and you can be certified for just one weld position and joint configuration, or you can become certified for all of them.

In Australia, the weld positions are listed by the AWS naming system.

Quality Control on Your Welds

When working on a work site, one of the aspects of your work as a welder is quality control. That includes following the welding procedure specification (WPS), which outlines the method and approach to be used for each job.

Quality control ensures the welds’ strength, integrity, and safety, forming an essential part of the structural and pipeline sectors.

This can involve inspecting for defects like undercutting, porosity, or excessive convexity, which compromise strength. To check the quality of a weld, you can:

- Do a visual inspection: Check the weld surface for uniformity and the absence of defects

- Test the weld’s strength: subjecting the weld to non-destructive tests to verify its robustness

Your results must meet the standards for the specific application, be it structural integrity or pressure containment. Proper pipe stands can also aid in maintaining stability and precision during these advanced welding tasks.

If a weld fails a quality control check, it will need to be removed and done again.

Understanding the different types of welding positions will help you considerably improve your welding skills. The positions, defined as flat, horizontal, vertical, and overhead, each demand specific techniques to achieve strong and durable joints. When working with fillet and groove welds, these can be performed in all four standard positions.

- Flat Position (1G/1F): easiest to master; you weld from above the joint

- Horizontal Position (2G/2F): more challenging; involves welding perpendicular to your body

- Vertical Position (3G/3F): uphill or downhill welding; requires good control of the molten pool

- Overhead Position (4G/4F): difficult; you weld from beneath the joint

The designations 1G through to 6G relate to the difficulty of the positions, with 6G being the hardest due to its requirement to weld at multiple angles and positions. By understanding these positions and being aware of the specifics and challenges associated with each position, you can ensure quality and produce professional-grade welds. Remember that practice makes perfect when refining your skills and boosting your confidence across all welding positions.