- MIG

How to Set Up Your MIG Welder for 1kg Spools

By Sarah Mazlin

16/02/2026

2 minutes

In This Article

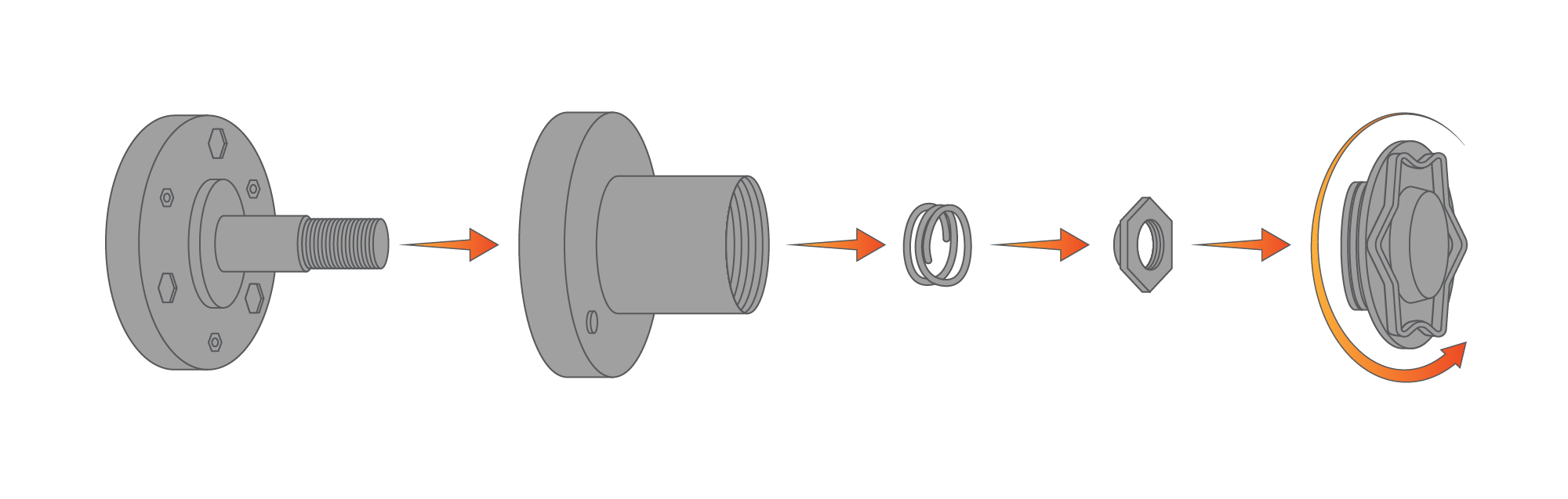

Changing a spool in your MIG machine is a fairly simple process. For 5kg (200mm) and 15kg (300mm) spools, it involves removing the retaining nut, sliding the spool on so that it lines up with the locating lug in the machine, and reattaching the retaining nut.

Loading a 1kg (or 100mm) spool into the machine is done in much the same way as a 5kg spool, with just a few extra steps.

Removing the Spool Holder

First, you’ll need to remove the retaining nut from the spool holder. Next, you’ll need to remove the spool holder that every machine comes pre-loaded with. To do this, the tensioner nut and spring need to be removed from inside it.

To take off the tensioner nut, grab a pair of pliers that fit inside the adapter (your MIG pliers should do the trick) and use them to unscrew the nut. Make sure to grab the spring that’s behind the nut when it comes off.

Remove the spool holder, so all that should be left in the machine is the bolt.

Installing a 1kg Spool

Slide your 1kg spool onto the bolt and place the spring and tensioner nut back on.

Tighten the tensioner nut enough that the spool won’t free spin, and when you stop pressing the torch trigger, the spool stops. However, just be careful not to tighten it too far. Too much tension can cause just as many problems as not enough tension. If the spool doesn’t spin at all, back the tension off just a little.

If you have a machine that is only suited to hold 1kg spools, like the VIPER MULTI 135, changing the spool is even easier. There’ll be no additional spool holder, so you’ll just have to take off the tensioner nut and spring, slide on the new wire spool, and screw the spring and nut back on.

Regardless of which size spool you’ve loaded in your welder, once it’s placed on the spool holder, you’ll need to feed the first bit of the new wire into the inlet guide, over the drive rollers and into the guide tube. That way, the wire will be locked into place between the drive rollers, and you’ll be able to release the spool and not have the wire unwind.

Now you can go ahead and feed your new wire through the torch, ready to weld.